Benefits of Anchor Bolt Inspections

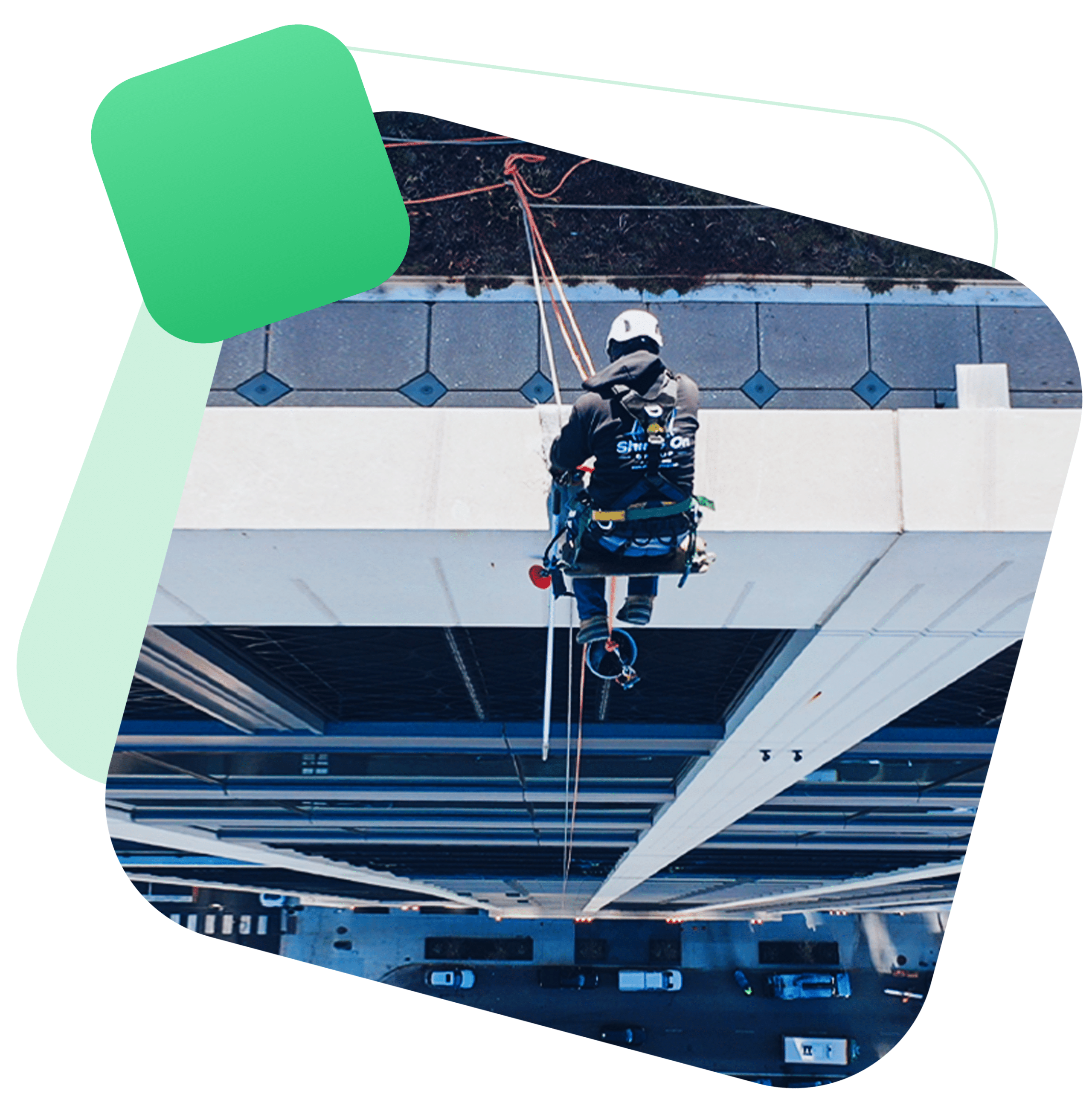

Roof anchors are common and extremely useful parts of fall protection systems utilized on tall buildings. These must be inspected regularly to ensure that they still serve their safety function and are still compliant with OSHA and meet all the roof anchor inspection requirements, especially when those regulations change and your anchors need to stay up to date. A thorough roof anchor inspection is a necessity that we can help you with at the Shine On Group. We’re the USA’s top anchor installation and fall protection experts, designing, installing, inspecting and certifying fall protection systems. We can inspect and recertify your anchor bolts to make sure you follow all regulations and your workers are safe, performing a thorough inspection and offer advice on changes and updates if necessary.