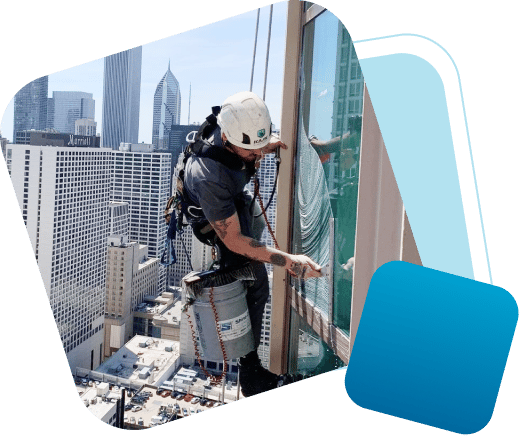

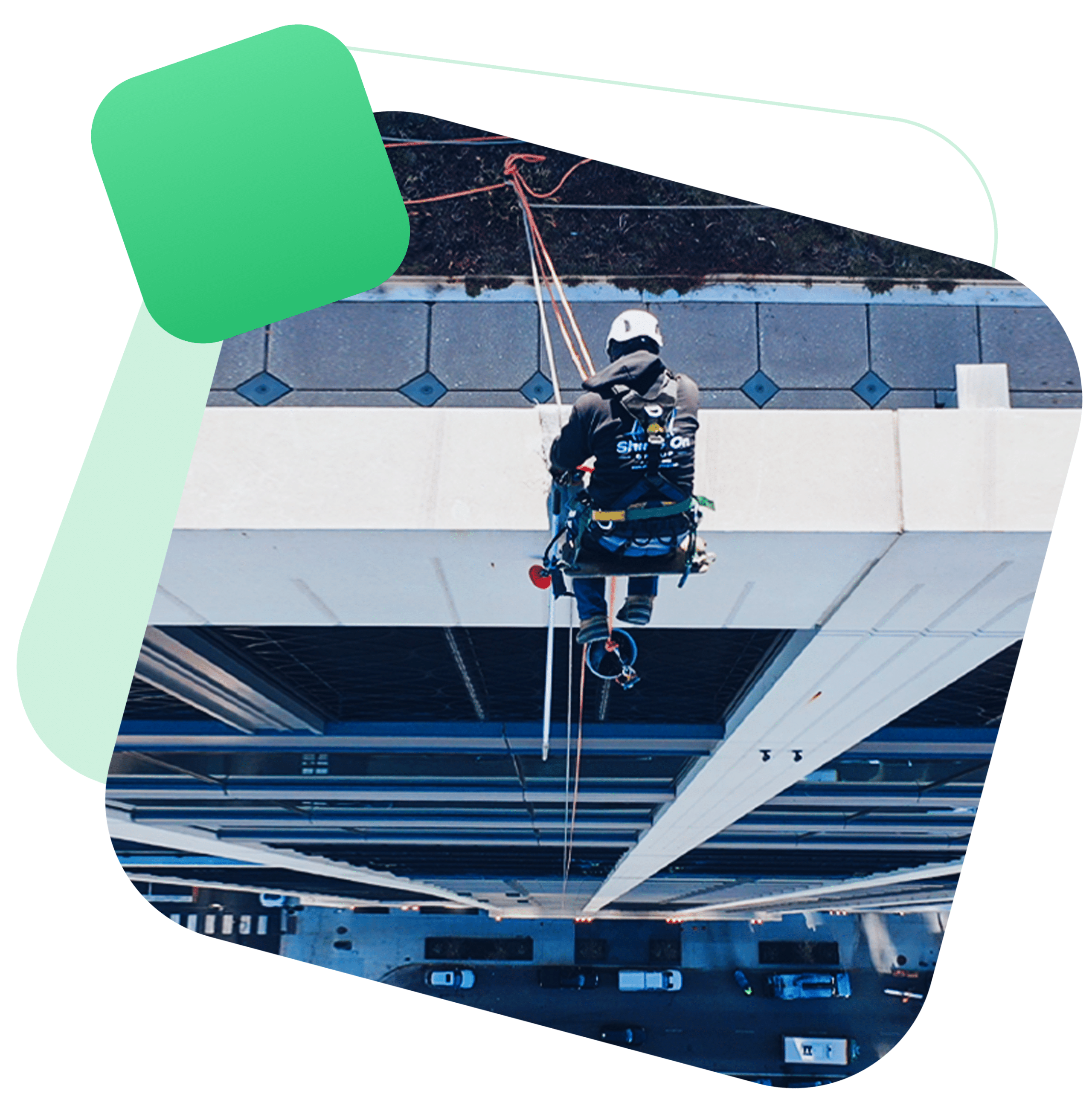

A roof anchor is a metal bar that is attached securely to a roof. It has an eye at one end through which cables are passed so that workers, who are attached to those cables, can move freely about but are prevented from falling. These cables literally provide a lifeline that avoids death or serious injury resulting from falls.

When undertaking any roof anchor installation, we will first assess the state of the roof. We will look for any defects on the roof and any signs of decay that will impair its integrity. The aim is simply to ensure that the roof has adequate strength to withstand the loads imposed by general working and, more importantly, by any falls that occur and which the system has to prevent.

We’ll always aim to install roof anchors securely and without damaging the roof. In particular, we want to ensure it remains watertight and we’ll always check for any existing water penetration before we start.

The installation method we use will depend on the type of roof material. This is typically concrete, steel, or reinforced timber and may be covered in a membrane such as asphalt and gravel, PVC, or bitumen. Anchors are often bolted through the substrate with steel plates above and below to ensure structural integrity or can be fixed with strong adhesive. Each method will have sufficient strength to withstand any likely loads and will preserve the integrity of your roof.