OSHA 1910.29 Fall Protection & Falling Object Guidelines You Must Know

Falling from heights or being struck by falling tools and materials are top causes of workplace injury. To reduce risk, OSHA’s 1910.29 standard outlines critical requirements for fall protection systems and falling object prevention.

What OSHA 1910.29 Covers

This standard explains how to properly use and design systems that protect workers from:

- Falling off elevated surfaces

- Being hit by falling objects from above

It also specifies requirements for:

- Guardrails, safety nets, and toeboards

- Personal fall arrest systems (PFAS)

- Vertical and horizontal clearance

Key Fall Protection Requirements

- Fall Clearance & Equipment Strength

Employers must:

- Evaluate clearance distance

- Use OSHA-rated equipment (anchors, harnesses, lanyards)

- Ensure all systems can withstand expected forces

- Falling Object Safeguards

To protect workers below, OSHA requires:

- Toeboards at least 3.5 inches tall

- Guardrail systems to prevent objects from being kicked or knocked off

- Canopies or netting where risk of falling tools/materials is present

- Specific System Standards

- PFAS: Max 6′ free-fall distance; system must limit arresting force

- Guardrails: 42″ high ± 3″, must withstand 200 lb of outward force

- Safety nets: Must be installed as close as possible beneath the work area

- Restraint Systems: Prevent access to unprotected edges

Who Must Comply With 1910.29?

This rule applies to all general industry employers where employees work at height or near drop zones. Documentation, system inspection, and worker training are all required for compliance.

Common Compliance Mistakes

- Relying on outdated anchor systems

- Skipping inspections or annual recertification

- Failing to secure overhead tools and equipment

- Not training contractors on your fall protection setup

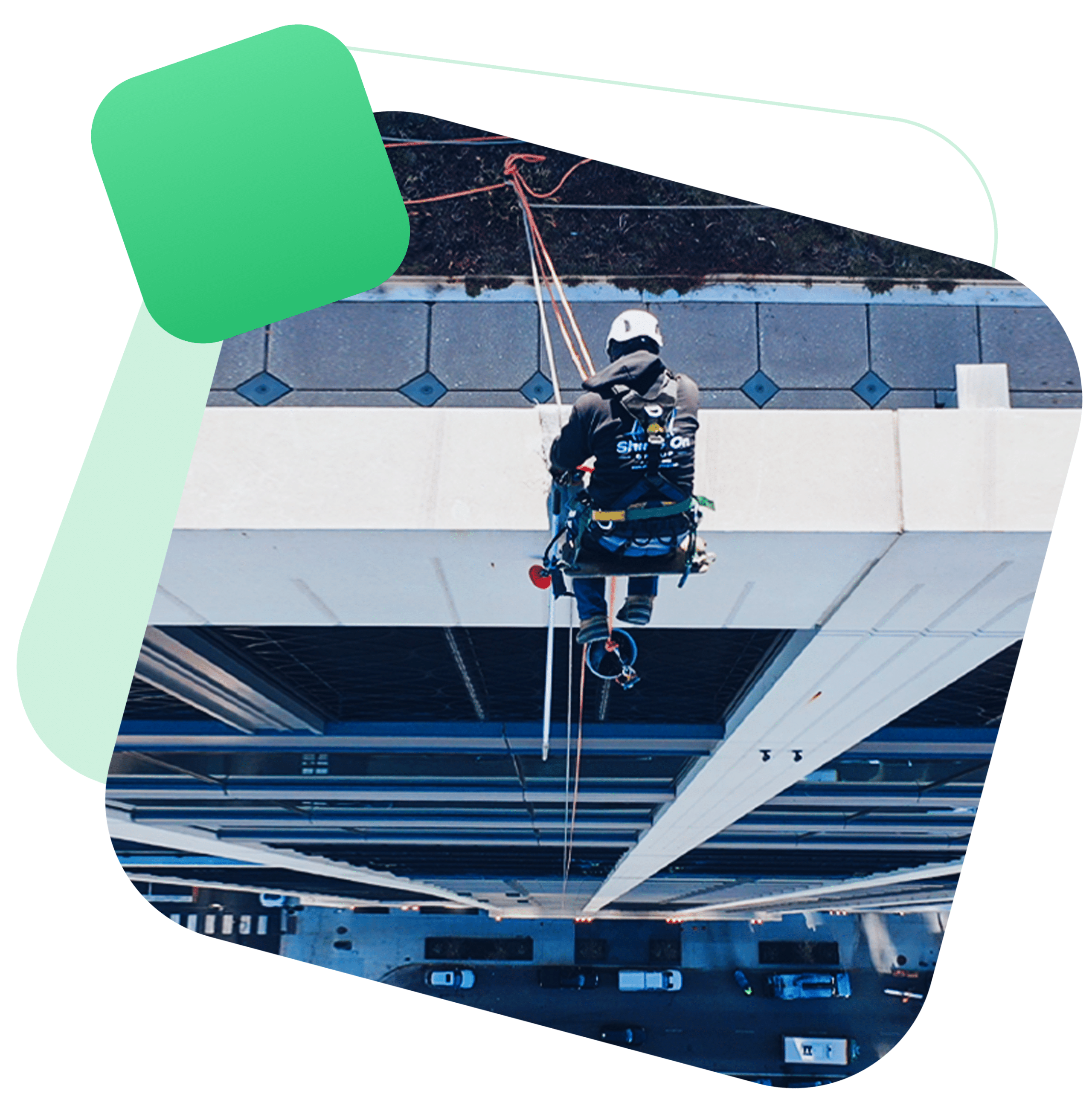

Shine On Anchors Keeps You Safe & Compliant

At Shine On Anchors, we help building owners:

- Evaluate existing fall protection setups

- Install OSHA- and ANSI-compliant systems

- Certify rooftop anchors and horizontal lifelines

- Conduct safety training and documentation reviews

Whether you manage a high-rise, warehouse, or school campus, our team ensures your site meets OSHA 1910.29 and beyond.

📞 Need help navigating OSHA 1910.29 compliance?

Contact Shine On Anchors today for an expert fall protection consultation.

Important things to know, review more articles OSHAs

OSHA’s – 1910.22 General Requirements

OSHA Recognized 3-Levels of Skill- Work at Height

Important Definitions per OSHA

OSHA’s – 1910.140 Personal Fall Protection Systems

OSHA’s – 1910.29 Fall Protection Systems & Falling Object Protection- Criteria and Practices

OSHA’s – 1910.28 Duty to have Fall Protection & Protection from Falling Objects

OSHA’s – 1910.30 Training Requirements

OSHA’s – 1910.23 Ladders- Fixed and Portable

Check our anchoring services

The OSHA 1910.29 Standard for Guardrails — Important Things to Know

When workers are operating at heights of four feet (1.2 meters) or more, anyone below that area will be exposed to the risk of people or objects falling. Any employee in the lower area must wear head protection that complies with OSHA standards.

The OSHA 1910.29 regulation specifies measures to prevent people or objects from falling from work areas. This includes the installation of toeboards and screens to prevent objects from falling but, more specifically, the use of guardrails that will help to prevent accidents. However, OSHA railing requirements are very specific, and you have to adhere to these standards to avoid non-compliance.

OSHA Guardrail Requirements 1910 You Must Follow

According to 29 CFR 1910.29, the top rail of guardrail systems must be capable of withstanding a downward or outward force of at least 200 pounds that is applied within two inches (5 centimeters) of the top edge. This force must not cause the top rail to deflect to a height less than 39 inches (99 cm) above the walking or working surface.

Other elements of the guardrail (such as mid rails, solid panels, and intermediate vertical members) need to withstand a lower downward or outward force of 150 pounds without failure.

The standard height of an OSHA-specified guardrail is 42 inches (107 cm), although 3 inches (8 cm) above or below this is acceptable. The top edge can in some cases be higher than 45 inches (114 cm) providing that other criteria are met.

A guardrail needs to include other components if there is not a wall or parapet with a minimum height of 21 inches (53 cm):

- mid rails that are installed midway between the working or walking surface and the top rail, so the gap between the horizontal members is not greater than 19 inches (48 cm)

- screens and mesh that can cover the entire area

- intermediate vertical members that must be no more than 19 inches (48 cm) apart.

All guardrails need to have a smooth surface, so they cause no injuries to workers and don’t catch on clothing. Top and mid rails have to be at least 0.25 inches (0.6 cm) across and must not overhang the terminal posts if they are likely to pose a hazard. Hand rails can be of various materials but steel or plastic banding is not permitted and there must be a minimum clearance of 2.25 inches (5.7 cm) from other objects so they can be gripped firmly

Ensuring Compliance with Professional Help

The regulations regarding guardrail requirements are complex and can vary depending on where they are used (open edges or stairways). They can also be changed so it’s difficult to keep up to date with the latest regulations.

It’s important you know exactly what is currently required because it’s easy to become non-compliant by omission. To avoid that happening and to ensure your workers are kept as safe as possible, you need to engage professional help.

Ignoring the problem is not an option and at Shine On Anchors we have the experience and knowledge to ensure you are always on top of safety needs. Get in touch and we’ll make sure all your guardrails and other safety systems are completely compliant and that your workers are protected from falls.