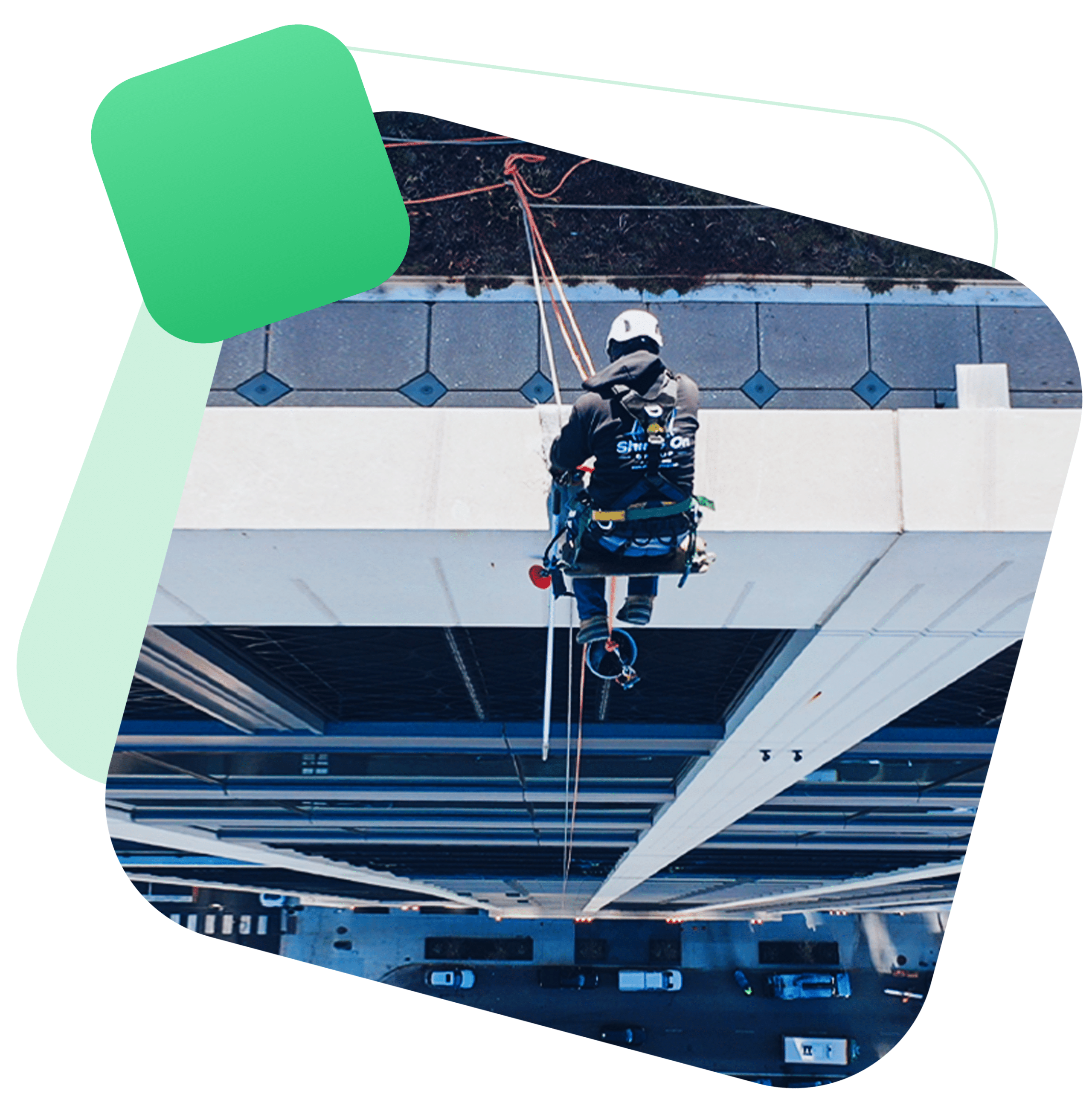

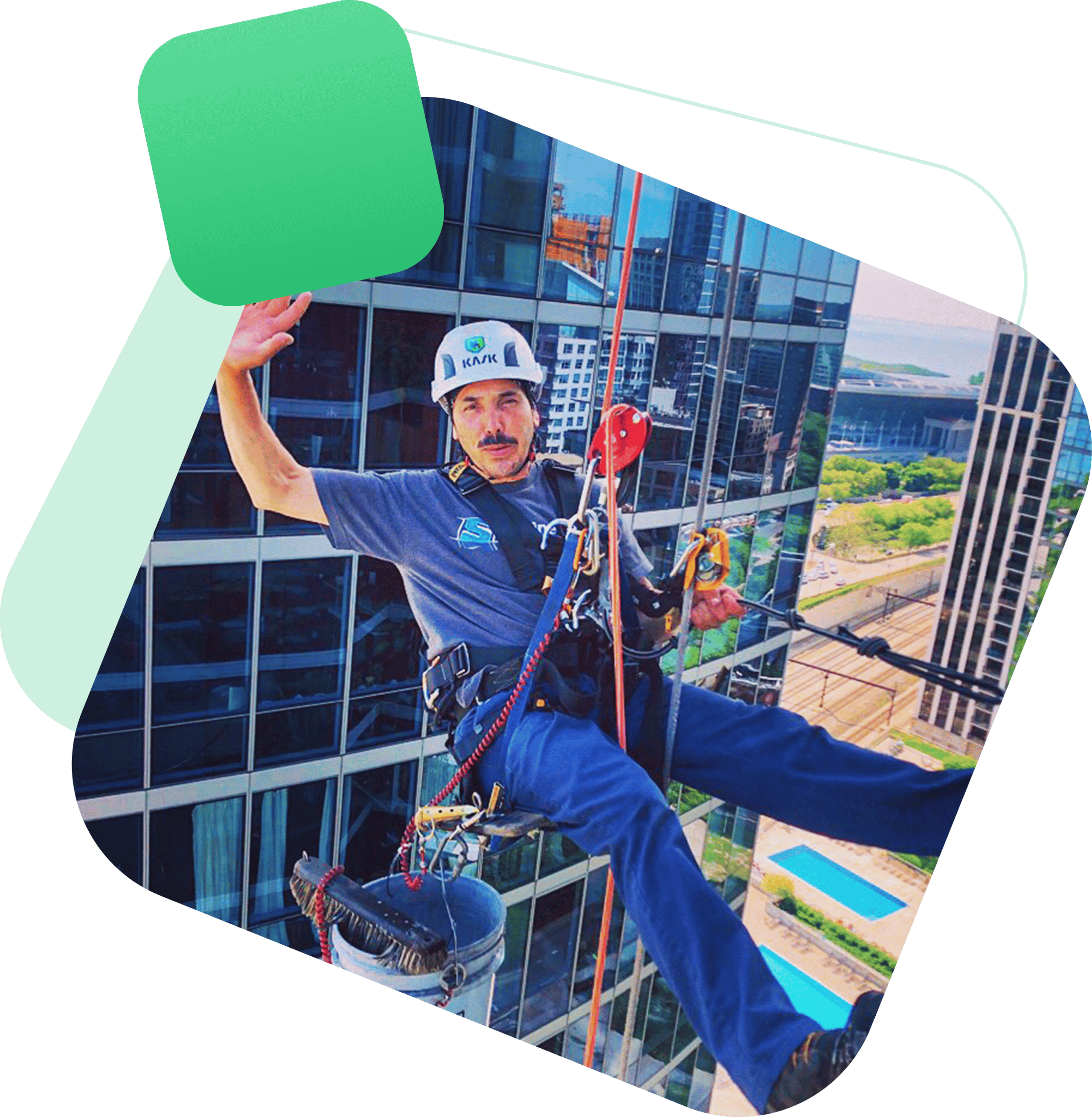

Roof anchor points support fall protection and fall arrest systems as well as rope descent systems. It’s vital, therefore, that they work effectively and correct anchor installation and use are only part of that. To ensure they continue to protect your workers from falls, it’s essential they’re checked and that fall protection anchor load testing is undertaken at specific intervals. In order to comply with regulations, recertification of equipment is also necessary.

Regulations regarding fall protection anchor testing are issued by the Occupational Safety and Health Administration (OSHA) and several other organizations. It’s important that you are aware of these regulations and that you comply with them.